|

|

|

Features |

|

|

다양한 용량의 모터 시험 대응 |

|

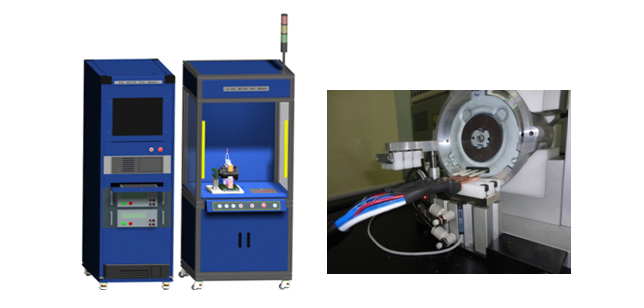

DC / BLDC / BLAC 모터 성능 시험기 |

|

DC / BLDC / BLAC 모터 전기 성능 시험기 |

|

DC / BLDC / BLAC 모터 마모 수명내구기 |

|

서보모터 및 히스테리시스 타입 모터 다이나노미터 사양 공급 |

|

Motor 및 Motor 제어기 연구개발 및 Motor 제조 단계별 사양 대응, 양산 검사기 EOL (End of Line) 자동화 검사기 공급 (약 100 검사항목 Tat Time 30~45 sec) |

|

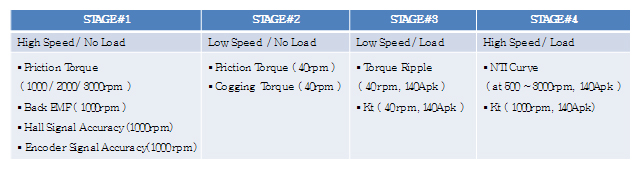

모터 성능시험기 시험항목 |

|

| |

- NTI 성능, Bemf, Cogging & Friction Torque, Torque Ripple, Torque Constant(Kt) 평가기능 |

| |

- BLDC 및 BLAC Motor의 Hall & Encoder Signal Accuracy 평가 기능 |

| |

- Cogging Torque, Bemf, Torque Ripple, Phase Current & Voltage 등에 대한 FFT 및 Order 분석 기능을 통해 모터 조립성 및 성능(출력,Ripple,진동) 원인 분석기능 |

|

|

모터 전기성능시험기 시험항목 |

|

| |

- Phase to Phase 저항 & Balance, Phase to Phase 인덕턴스 & Balance, 절연저항, 내전압 시험 기능

|

| |

- 수동시험 및 시험 Sequency 자동화를 위한 Panumatic Actuator를 이용한 상간 및 기기별

Switching 기능 및 고전압에 대한 Test Safety 기능 |

|

|

GUI Operation Program에 의해 시험 자동화 및 사용자 설정 기능, 실시간 모니터링 및 분석기능, Test Data Management 기능, 원격 MES(Manufacturing Execution System) Interface 기능 |

|

| |

|

Motor Dynamometer 사양 예 - BLAC EPS Motor Test Dynamometer |

|

|

|

| |

|

주요 System 사양 |

|

| 1) |

4 Stage Test Bench |

| - |

1 Stage : No Load Test : Friction, Back EMF, Hall & Encoder Signal Accuracy |

| - |

2 Stage : No Load Test with Harmonic Gear1/50 : Cogging Torque, Friction Torque |

| - |

3 Stage : Low Speed Load Test with Harmonic Gear1/50 : Torque Ripple,Torque Constant Kt |

| - |

4 Stage : High Speed Load Test : NTI, Torque Constant Kt |

| 2) |

Test Motor Operation & Load Control using Servo Motor Configuration |

| 3) |

0.1% Accuracy Torque Meter Configuration |

| 4) |

3,600 P/R Encoder Configuration |

| 5) |

Harmonic Gear Box include for Cogging Torque & Torque Ripple |

| 6) |

Programmable DC Power Supply System & PC interface |

| 7) |

Real time High Speed DAQ include (NI PCI or PXI System) |

| 8) |

Motor Driver Control Function include (Analog Voltage, CAN, Serial etc. user Confirm) |

| 9) |

3 Axis Motor Install Unit Configuration |

| 10) |

Manual or Auto Pin Connecting and Automatic Sequence Test Function |

| 11) |

Serial Communication Servo Control |

| 12) |

Test & Analysis Automation by GUI Program (Labview) |

| 13) |

Test Report Release Function |

| 14) |

Torquemeter Calibration Tool (Bar & Weight Unit) include |

| 15) |

UPS include for Control PC Power |

|

| |

|

주요 기능 |

|

| 1) |

Cogging Torque Test |

| - |

30/50 rpm |

| - |

Angle base Cogging Torque Measurement & Display |

| - |

Cogging Torque 평가를 위한 Cogging Value FFT 및 Order Tracking 분석기능 |

| - |

H/W Anti-Ailiasing Filter 기능 |

| 2) |

Friction Torque Test |

| - |

1000 / 2000/ 3000 rpm |

| - |

Angle base Friction Torque Measrement & Display |

| - |

Friction Torque 평가를 위한 Friction Value FFT 및 Order Tracking 분석기능 |

| 3) |

Back EMF Test |

| 4) |

Hall & Encoder Signal Accuracy Test |

| - |

Motor별 Hall & Encoder Signal 설정기능 |

| - |

Encoder Timing Error |

| - |

Bemf Error |

| - |

Edge to Edge Error |

| - |

Run Out(Peak-Peak) |

| - |

Number of Hall & Encoder Edge |

| - |

Hall Signal과 Bemf와의 방향성 |

| - |

Hall Signal 순서 |

| 5) |

Torque Constant(Kt) & Torque Ripple Test |

| - |

Max / Min / Ave. Torque |

| - |

Torque Ripple / Torque Constant(Kt) /Output Power / Eff./Difference |

| 6) |

NTI Curve Test |

| - |

Max / Min / Average Torque / RPM |

| - |

Phase Voltage(U/V/W) |

| - |

Phase Current(U/V/W) |

| - |

Main Power Supply Voltage(Vdc) |

| - |

Main Power Supply Current(Idc) |

| - |

Torque Constant(Kt) |

| - |

Mechanical & Electronic Power[W] , Efficiency[%] |

|

| |

|

GUI Program Sample |

|

|

| |

|

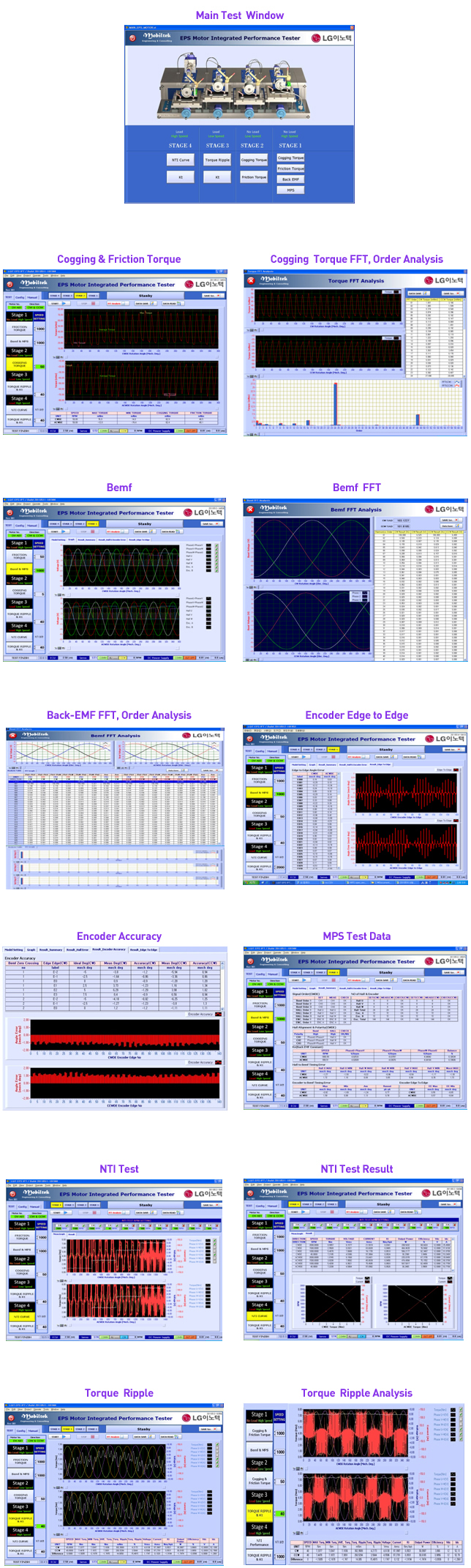

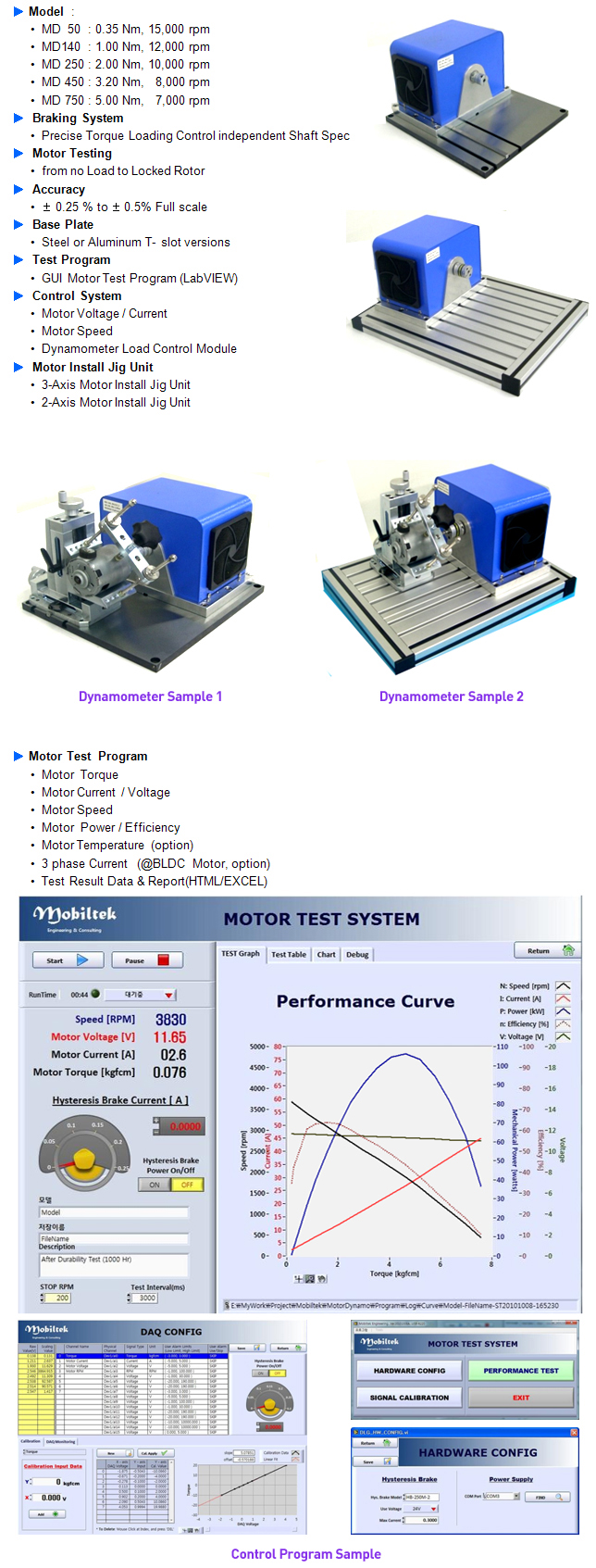

| Motor의 성능시험 및 부하내구시험을 위한 Motor Dynamometer로 부하 제어능력이 우수한 Hysteresis Brake를 기반으로 한 Hysteresis Brake Dynamometer 및 Dynamometer Controller, GUI(Graphic User Interface) 기반의 Motor Test Program으로 구성된다. |

| |

|

Features |

|

|

|

|

Motor 전기 성능 시험기 사양 예 |

|

|

| |

|

주요 System 사양 |

|

| 1) |

4 wire Micro Electrical Resistance Tester Configuration |

| 2) |

1A Constant Current Supply for Resistance Measurement |

| 3) |

Sine wave Current Supply by Programmable AC Power Supply for BLAC Inductance

Measurement |

| 4) |

Programmable DC Power Supply for BLAC Inductance Measurement |

| 5) |

Current Measurement Sensor include for BLAC Inductance Measurement |

| 6) |

LCR Meter DC / BLDC Inductance Measurement |

| 7) |

Motor Shaft Holding Fixture include by Air Actuator Unit |

| 8) |

Motor Phase Select Automation by Air Actuator Unit |

| 9) |

Manual Pin Connecting and Automatic Sequence Test Function |

| 10) |

Serial Communication Test Device Control & Data Measurement |

| 11) |

Test Motor Install Jig Unit with Toggle Cramp incldue |

| 12) |

Test & Analysis Automation by GUI Program (Labview) |

| 13) |

Test Report release Function |

| 14) |

Area Sensor Configuration for High Voltage Safety |

| 15) |

UPS include for Control PC Power |

|

| |

|

주요 기능 (Test 항목) |

|

| 1) |

Resistance Test |

| - |

Line to Line Resisance |

| - |

Line to Line Resisance Balance %

Measurement |

| 2) |

Inductance Test |

| - |

Line to Line Inductance |

| - |

Line to Line Inductance Balance % |

| 3) |

HI-Pot Test |

| - |

Max 1,000VAC Withstand Test |

| 4) |

Insulation Resistance Test |

| - |

Max 1,000VDC, Insulation Resistance |

|

| |

|

Test System - Sample |

|

|

| |

| |